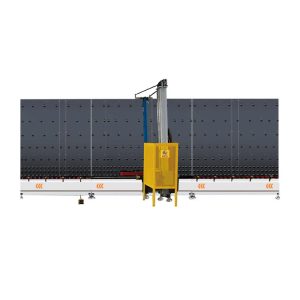

1.Product Introduction

The production line consists of a high-performance stainless steel washing machine, manual upper frame, automatic laminating device inside and outside the plate, automatic flat pressing device, and automatic discharge device.Can be upgraded and expanded according to user requirements.

Our insulating glass production line adopts imported electrical originals, sensors, and PLC to automatically control the operation of the equipment throughout the process.

Compact structure, economical and practical, high efficiency, easy maintenance.

2.Product Parameter :

| Min.glass size | 300mm×400mm |

| Max.glass size | 2500*3500mm |

| Washing glass thickness) | 3-15mm |

| Washing glass speed | 3-10m/min |

| Power supply | 380V 50Hz 34/35Kw |

| Insulating glass thickness | 15-50mm |

| Transmission glass speed | 45m/min |

| Compressed air | 800L/min |

| Flow volume | 0.8m3/min |

| Air pressure | 1Mpa |

3.Product Advantage :

1. Achieve the functions of outside and inside assembly,automatically fill argon gas and stepped glazing

2. Adopts the PLC to control the working condition and touch screen

3. Automatic detect coated surface of coating glass and Low-E glass

4. Aluminum spacer and glass automatic positioning system

5.Automatic detect the length and height of glass, automatic adjust the best gas filling time

6. Automatic gas filling press machine adopt 4 servo motors, which has assembling, pressing and automatic

gas filling functions. Ensure the insulating glass argon gas concentrate ≥ 85%

7. It has remote monitor and program upgrade functions.

Reviews

There are no reviews yet.