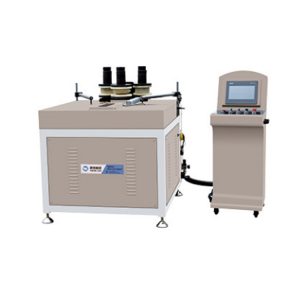

CNC 3-axis End Milling Machine is suitable for the molding processing of various profile end faces and step surfaces (such as reinforced mullions, system door and window frames, flush mullions for doors and windows, sunrooms, curtain wall beams, etc.), to adapt to the coordination of different cross-sectional profiles and secure the profiles in place.

The CNC numerical control system, along with CNC servo motors, regulates the tool’s vertical and horizontal movements during milling, with controllable travel distances. The feed speed is adjustable, and there is a rapid tool retraction feature. With a large processing range, user-friendly operation, and high production efficiency.

Technical Parameters

| Model | CNC-300B |

| Total Power | 5.2kw |

| Spindle Motor Power | 3kw |

| Spindle Motor Speed | 2850r/min |

| X-axis Travel | 600mm |

| Y-axis Travel | 150mm |

| Z-axis Travel | 360mm |

| Working Desk Size | 330*180mm |

| Overall Dimensions | 1750*1300*1600mm |

| After-sales Service Provided | Engineers available to service machinery overseas |

Ultra-long processing lifespan carbide saw blades High-precision spindle and saw blade ensure cutting quality.

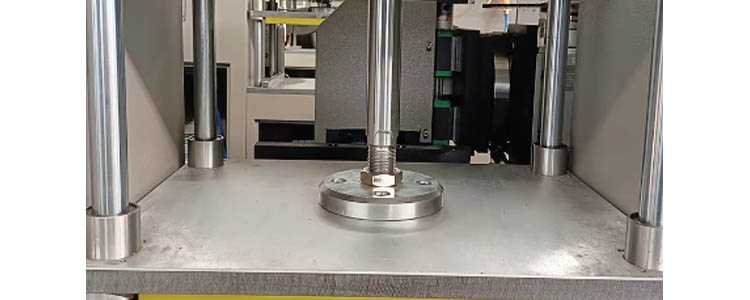

Compression workbench Prevent profile movement and ensure milling accuracy.

CNC control system

CNC servo motor controls the tool’s movement in the vertical, horizontal, and lateral directions. Milling stroke is adjustable, feed speed is variable, and the retraction speed is fast.

Reviews

There are no reviews yet.