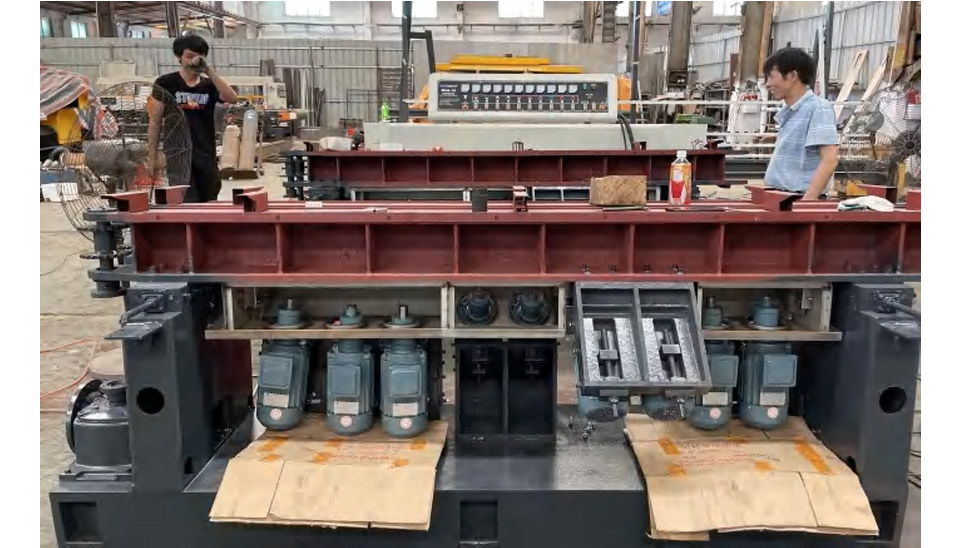

11325 is specialized in edging and polishing glass. It can edging and polishing the flat edge at one time. The transmission drive adopts mechanical step-less speed change machine’s speed, with large adjustable range and stable speed change. Both the front and rear girders and the bed of the

base are made of thickened and enlarged cast iron, which has good stability after high temperature annealing and aging treatment. The equipment is easy to operate, stable in performance and reliable in quality. It is the first choice for the majority of glass companies. It can be equipped with the PLC per customer’s requirement.

2.Technical parameter

| Voltage/HZ | 380V/50HZ (according to customer) |

| Range of speed | 0.5-6m/min |

| Min.processing glass size | 80*80mm |

| Max.processing glass size | 3000*3000mm |

| Processing glass thickness | 3-25mm(it can be customized) |

| Overall dimension(L*W*H) | 6800*1000*2500mm |

| Total Power | 24.6Kw |

| Weight | 3500kg |

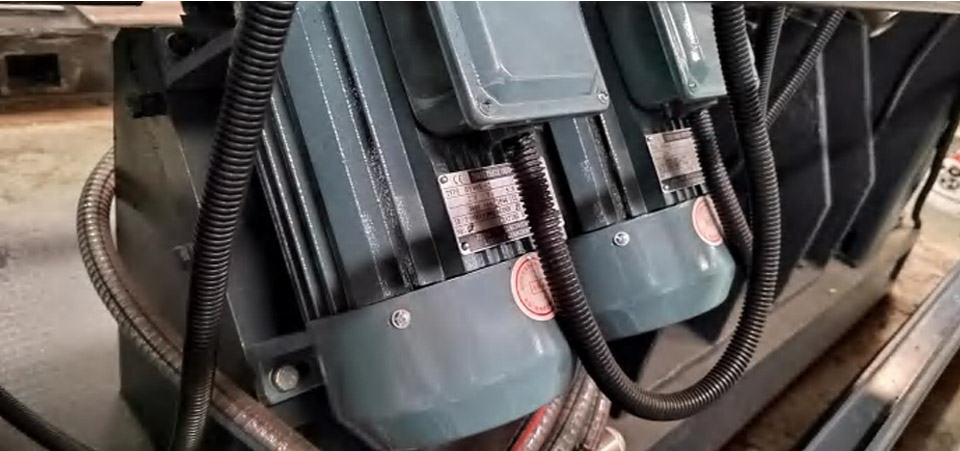

| Remark | 11 motors |

3.Main component parts

1.The base and girder are made of high-quality and thickened casting materials. After high-temperature annealing and aging treatment, they have stable structural performance and can bear large processing load.

2.Lobster type brand is adopted for front and rear pressing plates, featuring strong wear resistance, stable structure and performance.

3.The polishing head motor adopts the special polishing head motor of the most durable brand in Guangdong: Jianqiang motor.

4.The CVT adopts the products of Guangdong Xingguang star drive and Qiangzhu turbine box company.

5.The main electrical parts are products of Delixi Electric Co., Ltd.

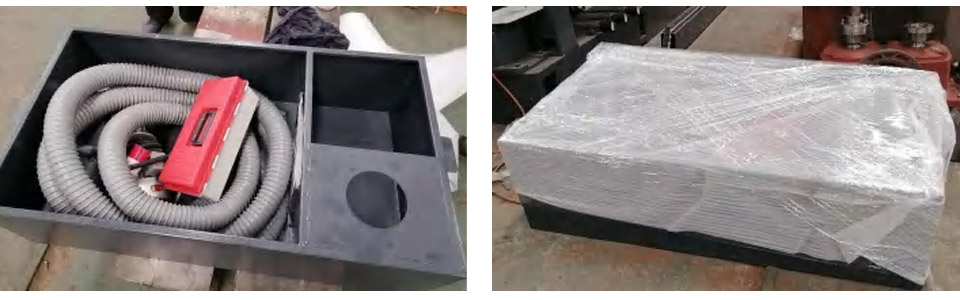

6.The water tank is made of stainless steel by welding, which has stable water-proof performance and is not easy to rust. The high-temperature wire brush is used for the water sweeping, which is not easy to fall off and durable.

Reviews

There are no reviews yet.